What is supply chain management automation

Supply chain automation involves the use of specialized software to reduce the workload of manual and repetitive tasks. It employs various technologies, such as digital cloud solutions, AI, data analytics, and robotics services.

Companies are increasingly reliant on logistics optimization, with 45% of supply chains expected to be automated by 2035.

Supply chain automation tools: Comparison list

| Tool | Best For | Features | G2 Rating |

|---|---|---|---|

| Outvio | eCommerce, B2B, Retail | Order automation, 100+ carriers, tracking, returns, built-in support | 4.8 |

| Odoo SCM | SMEs across sectors | Modular ERP, inventory, sales, customizable apps | 4.3 |

| SAP SCM | Large enterprises | Industry modules, analytics, ERP integration | 4.3 |

| Infor SCM | Manufacturing, Healthcare | Real-time data, warehouse, marketing, cloud-based | 3.9 |

| Oracle SCM | Global manufacturers | AI forecasting, CRM, logistics | 4.1 |

| Generix Group | Retail, Logistics | WMS, traceability, logistics, inventory | 4.3 |

| Sage X3 | Mid-size businesses | Finance, CRM, logistics, multi-language | 4.2 |

| Blue Yonder | Retail, Distribution | AI forecasting, supply chain visibility, scalable | 4.3 |

| OpenBoxes | Healthcare Logistics | Open-source, inventory, reports, tracking | N/A |

| Bizagi | Process automation | Workflow builder, analytics, BPM, DPA | 4.6 |

| Unleashed | Inventory management | Real-time inventory, sales, mobile access | 3.9 |

What is a supply chain automation software and why companies need it

Supply chain automation software is a solution designed to automate a company's logistics processes. Its functionalities include order processing, stock control, procurement, and transportation operations.

Deloitte states that 79% of supply chains using automation systems grow above the typical average. Some reasons include:

- Reduces processing time, facilitating smoother operations

- Enables reallocating human resources to more valuable activities

- Provides real-time visibility into all stages of the supply chain

- Helps adjust production and distribution strategies quickly

- Keeps companies ahead of the competition and swiftly capitalizes on market changes

Using software to automate your supply chain workflow is critical for remaining competitive and scaling your business over time.

Best supply chain automation software solutions

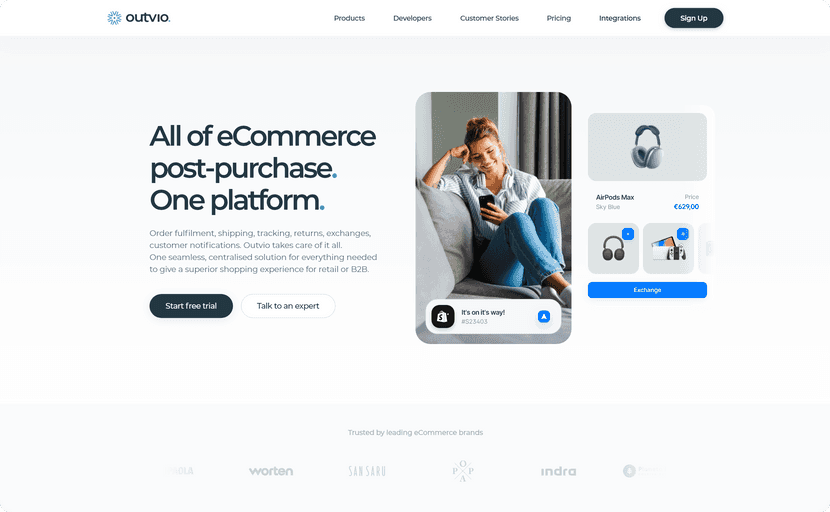

1. Outvio

Outvio is a solution that allows you to automate a large part of the transport and order operations in eCommerce. Designed to improve the shopper experience and facilitate the working environment of large retailers, it offers fulfillment services, transport integrations, returns, tracking, business analytics, and customer service support.

G2 Rating

Pros

- Priced well below that of an ERP

- No IT knowledge required, as it's an off-the-shelf solution

- Connects your business with carriers worldwide and optimizes transport operations

- Centralizes all eCommerce ordering operations in a single software

- Personalisation, cross-selling and integrated customer service system

- Bundles functionalities from different software to automate the eCommerce supply chain in a cost-effective way

Cons

- No inventory management functionality at the moment

- Limited manufacturing and production functionalities

For: eCommerce, B2B, or retail businesses that need to efficiently manage shipments and logistics

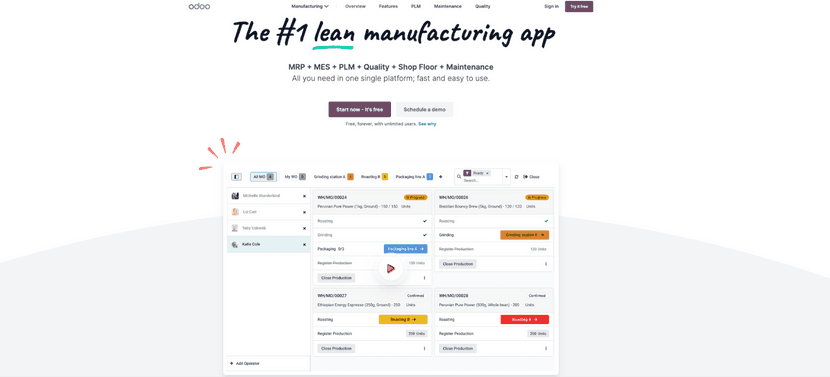

2. Odoo SCM

Odoo is an ERP system that manages various aspects of a business including production, transportation, inventory, sales, marketing, and analytics. It offers a comprehensive suite of applications that can be customized to fit different business needs.

G2 Rating

Pros

- Being open-source, it offers greater flexibility for customization and integration

- Large community of developers and users for support and shared solutions

- Allows businesses to start with basic modules and add more as needed, reducing initial costs

Cons

- Upgrading to new versions can be complex and may require re-implementation of customizations

- May lack some advanced features found in more specialized or higher-end ERP systems

- Dependence on external partners for significant customizations and support

For: small and medium-sized enterprises in various sectors such as manufacturing, distribution, and services

3. SAP SCM

SAP is an ERP system known for its ability to centralize tasks and information across a company. It includes modules that can be expanded to add new functionalities, including specific solutions for supply chain management automation, aligning operations across departments.

G2 Rating

Pros

- Offers tailored solutions for various industries, enhancing relevance and efficiency

- High level of security and compliance features, suitable for large enterprises

- Advanced reporting and analytics capabilities for informed decision-making

Cons

- Requires significant IT resources for implementation and maintenance

- Customizing the system to fit specific needs can be time-consuming and costly

- Extensive training required for staff to utilize the system effectively

For: large companies in sectors such as manufacturing, retail, distribution, and services that require comprehensive and scalable management

4. Infor SCM

Infor SCM is a cloud-based solution that provides comprehensive control over manufacturing, marketing, and warehouse management processes for large manufacturers. It offers synchronization with stakeholders to ensure automated operations across the supply chain.

G2 Rating

Pros

- Provides real-time data and insights, enhancing decision-making

- Facilitates collaboration between different departments and external partners

- Highly scalable solution, suitable for growing businesses

Cons

- Can have long implementation timelines due to its comprehensive nature

- Costly Customization: Customizing the platform to fit specific needs can be expensive.

- Vendor Dependency: Heavy reliance on Infor for support and updates

For: manufacturing, distribution, healthcare and automotive companies

5. Oracle SCM

Oracle SCM is a service provided by Oracle that manages various aspects of business operations including production, transportation, sales, marketing, and customer service. It offers advanced analytics for better decision-making and report generation.

G2 Rating

Pros

- Covers a wide range of SCM needs with integrated modules

- Uses AI and machine learning for enhanced analytics and forecasting

- Suitable for global businesses with support for multiple languages and currencies

Cons

- Complex to implement, requiring significant time and expertise

- High total cost of ownership, including licensing, implementation, and maintenance

- Can be overwhelming for users due to its comprehensive nature

For: distribution, manufacturing, health and industrial production companies

6. Generix Group

Generix Group specializes in warehouse management, stock keeping, and supply chain traceability. It's tailored for eCommerce businesses that need robust inventory management and logistics capabilities without managing production or manufacturing.

G2 Rating

Pros

- Tailored functionalities for eCommerce logistics and inventory management

- Can scale with the growth of the business

- Strong customer support and professional services

Cons

- Less flexible for businesses outside the eCommerce sector

- May face difficulties integrating with non-eCommerce systems

- Limited availability of custom features outside its primary focus

For: retail, distribution, logistics and manufacturing companies looking for collaborative and flexible solutions

7. Sage X3

Sage X3 offers complete supply chain management software with functionalities covering production, transportation, storage, sales, marketing, automation, logistics, finance, and CRM. It's customizable to meet specific business needs and integrates various operations into a single platform.

G2 Rating

Pros

- Seamlessly integrates with various third-party applications, enhancing functionality

- Supports multiple languages, currencies, and regulations, suitable for international businesses

- Intuitive interface, making it easier for users to adapt and utilize

Cons

- Requires significant IT resources for implementation and maintenance

- Customizing the platform can be costly and time-consuming

- May be overly complex for smaller organizations with simpler needs

For: medium-sized companies in sectors such as manufacturing, distribution, and services

8. Blue Yonder

Blue Yonder provides supply chain management solutions that optimize operations from production to distribution. It leverages advanced analytics and machine learning to enhance forecasting, planning, and execution across the supply chain.

G2 Rating

Pros

- Uses AI and machine learning to provide highly accurate demand forecasting

- Offers complete visibility across the entire supply chain, from production to distribution

- Highly scalable, suitable for both medium and large enterprises

Cons

- Long implementation timelines due to its comprehensive nature

- High initial and ongoing costs can be a barrier for smaller businesses

- Steep learning curve, requiring extensive training for effective use

For: retail and distribution companies in need of advanced demand planning tools

9. OpenBoxes

OpenBoxes is an open-source sectoral logistics software designed for supply chains related to the healthcare industry, although it can also be used in other sectors. The tool helps manage different tasks: inventory management, product tracking, counting, sales, and customer management or report generation

G2 Rating

-

Pros

- Free to use, with the ability to customize the software to meet specific needs

- Designed specifically for healthcare logistics, making it highly specialized

- Active community providing support and shared improvements

Cons

- May lack advanced features found in commercial supply chain management solutions

- Requires significant technical expertise to implement and maintain

- May not scale well for very large organizations or complex supply chains

For: companies in need of customised warehouse management and logistics operations solutions

. Bizagi

Bizagi specializes in digital process automation (DPA) and business process management (BPM). It helps organizations model, automate, and optimize processes for efficiency, cost reduction, and agility. Bizagi offers a user-friendly interface for designing workflows, integrating systems, and deploying applications across departments.

G2 Rating

Pros

- Integrates well with existing systems and databases, enabling seamless collaboration

- Provides robust analytics and reporting to monitor process performance

- Supports both cloud-based and on-premises deployment options, offering flexibility

Cons

- Setting up and managing large-scale deployments can be complex

- Costs for licensing and maintenance can be significant

- Extensive customization may require deeper technical expertise

For: companies in various sectors looking to automate and optimise business processes, including supply chain management

11. Unleashed

Unleashed is a cloud-based inventory management software designed to help businesses manage their inventory, sales, and purchasing. It provides real-time visibility of inventory levels across multiple locations, allowing businesses to optimize stock levels, streamline operations, and make data-driven decisions.

G2 Rating

Pros

- Scales to meet the needs of businesses of all sizes, facilitating growth and operational expansion

- Offers customizable reports and analytics for detailed insights into inventory performance, sales trends, and profitability

- Accessible via mobile devices, providing flexibility and responsiveness for managing inventory and sales on the move

Cons

- Limited to automating stock-related supply chain processes

- Costs associated with licensing and ongoing subscription fees may be prohibitive for smaller businesses or startups

- Setting up and configuring Unleashed Software can be complex

For: small and medium-sized companies in retail, manufacturing, and distribution sectors seeking efficient inventory management solutions

How supply chain automation software helps you: examples of good practices and operations

Automating order processing and fulfillment management

This software automatically validates order details, updates inventory in real-time, schedules fulfillment, and generates invoices and shipping labels. It ensures orders are processed quickly and accurately, minimizing errors and ensuring smooth fulfillment.

Forecasting demand and optimizing inventory automatically

Using historical data and market insights, this software predicts future product demand. It helps businesses optimize inventory levels, plan production schedules, and make informed procurement decisions efficiently.

Automating comprehensive warehouse operations

In warehouses, this system automates inventory tracking, order picking and packing, and shipping. It optimizes routes, enhances inventory accuracy, and reduces operational costs by streamlining warehouse operations.

Streamlining supplier collaboration

This software automates order placement, confirmation, and shipment tracking with suppliers via EDI or APIs. It ensures timely procurement, reduces lead times, and maintains optimal inventory levels throughout the supply chain

Integrated automated returns management

For returns, this system automates RMA authorization, label generation, item tracking, and refunds/replacements. It accelerates return processes, improves customer satisfaction, and reduces administrative overhead associated with returns.

Real-time supply chain visibility and proactive management

Providing centralized dashboards and analytics, this software integrates real-time data on inventory, order statuses, and shipment logistics. It enables proactive decision-making, rapid response to changes, and overall efficiency improvements in supply chain operations.

Optimized automated shipping processes

This system selects optimal carriers, automates label generation, schedules pickups, and provides real-time tracking updates. It streamlines shipping operations, reduces costs, and enhances delivery accuracy to improve customer satisfaction.

Automated customer order status updates

It automatically updates customers via order notifications, email, or SMS on order processing, shipping status, and estimated delivery times. This enhances transparency, reduces customer inquiries, and improves overall customer satisfaction during the order fulfillment process.

Data-driven automated reporting, analytics, and improvement

Analyzes key performance indicators (KPIs) such as inventory turnover, order fulfillment metrics, and supply chain costs. Generates insightful reports, dashboards, and visualizations to support strategic decision-making, drive continuous improvement initiatives, and optimize overall supply chain performance.

What to consider when choosing an SCM automation system?

Not all supply chain automation software is suitable for every company.

Depending on the size of your operation or your industry type, you may need to choose one software over another.

Here are some tips to keep in mind when choosing one:

Integration Capability

Ensure the system can integrate seamlessly with your existing software infrastructure, including ERP (Enterprise Resource Planning) systems, CRMs (Customer Relationship Management), and other essential business tools.

Scalability

The ability of the SCM system to grow with your business is crucial. It should accommodate increasing volumes of data and transactions without significant performance degradation.

Functionality and features

Evaluate the features offered by the SCM system. This includes inventory management, demand forecasting, order processing, logistics management, and analytics capabilities. Choose a system that aligns with your specific business needs.

Customization Options

Different businesses have unique requirements. The SCM system should allow for customization to adapt to your specific workflows, processes, and business rules.

User Interface and Ease of Use

A user-friendly interface is essential for adoption across your organization. Training requirements and ease of navigation can impact how quickly your team can leverage the system effectively.

Cost

Evaluate the total cost of ownership, including initial setup costs, licensing fees, maintenance costs, and potential savings from efficiency gains. Consider both short-term and long-term costs.

Investing in an automated supply chain is a highly beneficial strategy for almost any company. With the right software, you will not only reduce the operational costs of your supply chain but also enable other features to keep your customers happy.

To find out if software is suitable for automating your supply chain, ideally, you should choose one that specializes in your industry and request a demo. If you are in eCommerce, Outvio will be happy to assist you.

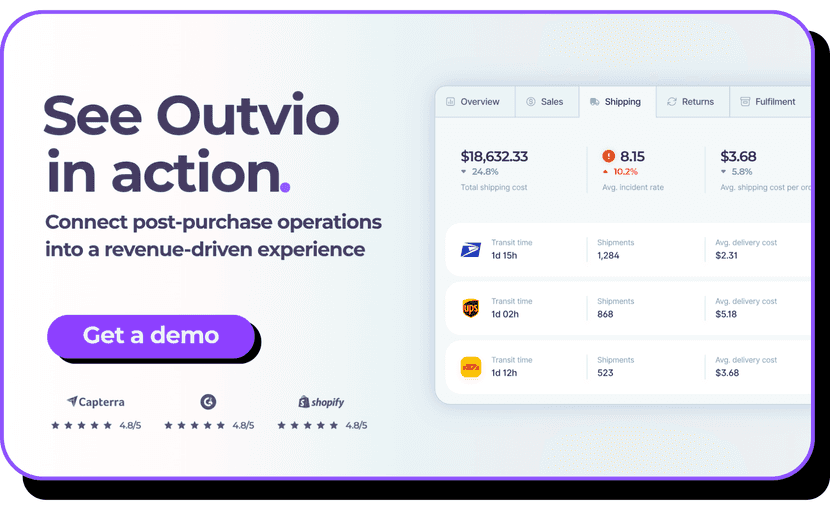

Outvio, the best supply chain management software for eCommerce and retail

Outvio centralizes shipping, tracking, returns, and customer communication in one platform—so you don’t need multiple tools. It connects with 100+ carriers, automates order processing, and optimizes delivery costs in real time.

Unlike generic ERPs, it’s built specifically for eCommerce and retail, with features like branded tracking and automated exchanges. With Outvio, retailers turn logistics into a growth engine, not just a backend task.

Find out why Outvio is the best solution to automate your supply chain in eCommerce. Book a demo today.