Moving towards more efficient warehouse operations isn’t an easy task. As the number of SKUs grows and different types of products become available, manufacturers, distributors and retailers start looking for ways to reduce costs, speed up order processing, increase the profitability of the business and improve customer satisfaction.

Warehouse slotting can be a powerful tool for all businesses that physically deal with product storage and picking and packing processes. Efficient slotting can reduce labor costs by up to 20% and leverage between 40% and 60% of the time picking and packing operators spend processing orders.

What is slotting?

The process of organizing and allocating the stock in the warehouse for maximum efficiency is called slotting. Slotting uses the warehouse space in the smartest way to ensure fast picking and packing and higher customer satisfaction.

To implement slotting, different businesses use different factors to organize warehouses in a smart way. A business might focus on the size of the items, their weight, how often they’re sold or the sales forecast. It all depends on the nature of the products, the number of SKUs they deal with and their turnover.

Slotting can be done on a large scale — when the entire warehouse is optimized for efficiency — or on a smaller scale (micro-slotting). It unlocks opportunities for growth without the need to change the infrastructure or hire more personnel, but it does come with an investment of time.

Macro-slotting vs. micro-slotting

When it comes to slotting, there are two ways of implementing it in a warehouse. The first way is macro-slotting. This approach is used when the strategy is implemented for the whole warehouse and inventory. Macro slotting is closer to what we describe in our article on warehouse layout design.

Micro-slotting, on the other hand, is focused on specific items; it calls for each SKU to be placed at its optimal location for faster picking, regardless of the dimensions of the warehouse or the placement of other products.

Benefits of slotting

Although warehouse slotting utilizes resources from a business, the resulting benefits typically make it a wise decision — as long as customer satisfaction and peak performance are priorities for the distribution center, manufacturer or retailer. Here are some of the most important advantages:

Overview of top performing items

Instead of storing top-selling items in an inconvenient area while out-of-season or less popular products are found on the fast-moving shelves, slotting considers these and other factors to create optimal picking routes.

Slotting allocates the stock in a smart way that prevents bottlenecks and supply chain crises because all top-performing items — most likely those that need to be restocked more frequently or in bigger quantities — are separated from slow-moving items. This helps managers avoid stockouts and increase customer satisfaction thanks to shorter delivery times and the reduction of canceled orders due to a lack of stock.

When implemented correctly, warehouse slotting enables you to both cut down on human errors during the picking process and better leverage the space you have, all without jeopardizing the efficiency of the operations.

Increased efficiency

As the sales volume increases, warehouse operations generally become more complex, resulting in more frequent bottlenecks while products are allocated or collected.

Without slotting, warehouse operators need more time to fulfill orders. However, when everything’s in its proper place, there’s a significant increase in the staff's productivity, thanks to shorter travel times, fewer picking and packing errors and a clear vision of where each product is, at all times.

Outvio’s Advanced Fulfillment System verifies that each item that goes into a package should be there simply by scanning its barcode. 100% error-free orders, every day. Try it out now!

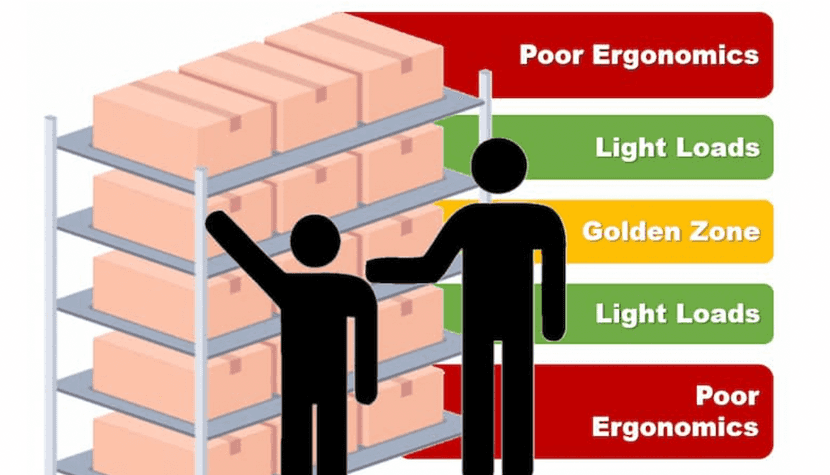

Apart from the clear benefit of faster order processing, inventory slotting can be used to separate all products that need to be moved by bulky equipment from the smaller and lighter items. That way, you can avoid creating bottlenecks in fast-moving aisles. Furthermore, heavier items can be picked first and placed below those that are lighter and likely more fragile, thereby reducing the number of broken items during the picking process.

Higher customer satisfaction

With faster order processing comes faster deliveries and, as long as the slotting analysis was done correctly, there should be few, if any, errors in the picking and packing process. Logically, this increases customer satisfaction overall and potentially leads to a higher repurchase rate too.

Source: SoftDoit

Moreover, thanks to better control of the stock levels for each SKU — and a better vision the items that are top performing and those that have slower turnover — the business can better predict purchasing habits, meeting customer demand and reducing stockouts.

Although warehouse slotting may seem like something that only impacts warehouse operations, it actually brings considerable benefits for the producer or retailer. Slotting uses available resources to ease the processes of expanding a business with new products and removing those that aren’t successful, without the need to invest in bigger facilities or hire more employees.

What are the best practices for a slotting strategy?

There are three main steps that are fundamental for any successful slotting strategy:

Slotting analysis

In order to organize the items in a smart way, the first step is to collect data about the products. Ideally, you want to start with data covering about a year’s worth of time. In this way, you’ll be able to prepare for seasonal spikes and drops of certain products which will affect the re-ordering frequency and alter the location of such items in the warehouse.

However, not all warehouse slotting strategies are organized by the sales volume. Businesses that produce or distribute products with dimensions or weights that vary considerably can also choose to sort products according to those factors.

For example, a warehouse may choose to store pillows or lamps in one aisle — let’s call it Aisle A — and leave bigger pieces of furniture in Aisles B and C, according to their weight. Chairs and tables could go to Aisle B, while Aisle C could store bed frames, mattresses and sofas.

Obviously, this organization method only makes sense when the dimensions and weight are very different or when certain items need special equipment for picking and packing.

For most online retailers, the size and weight of each product won’t differ more than a couple of kilos, making sales data crucial for slotting optimization.

Slotting warehouse organization

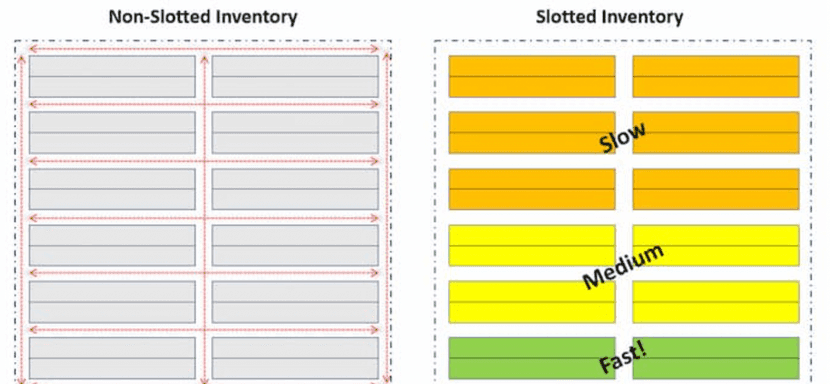

Once all the data you need is available to you, it’s time to organize the warehouse with the slotting strategy. In order to do this, you’ll need to choose a method or “map” to allocate the products in a smart way. Most typically, warehouses opt for an ABC inventory classification. This means setting up a minimum of three areas (fast-moving, average-moving and slow-moving items).

In the case of a fashion store, the “A zone” is allocated to top-sellers, the “B zone” hosts limited-edition products and the “C zone” stores out-of-season items or those that are predicted to sell less often. In this way, pickers can have easy and fast access to the most popular SKUs, and it’s even better if you place frequently-bought-together items next to each other. Doing so can speed up the picking time.

Luckily, you don’t need to do all of this manually. There are slotting tools that analyze the data and provide a classification of the products according to the factor that you’ve selected for organizing the warehouse.

The top 50% will generally be the top-sold items, and they’ll be placed in the “A zone.” The next 25% will go in the “B aisle,” and the last 25% in the “C aisle.” If needed, additional aisles can be created to store other products of different characteristics.

Review your slotting strategy

Now that items have been organized for efficiency, the next step is to leave warehouse operators to test the efficiency of your slotting strategy. Check with them about the impact that the new layout and stock location system has had on their work and figure out ways to improve it.

There may be a need to remove some SKUs from your product catalog, and you may find that some products are doing so well that it’s worth expanding those product types or products that complement them.

Obviously, we wouldn’t recommend you rely purely on the observations of warehouse workers; there are also specific metrics that can shed light on the effectiveness of the improvements. Those include the number of returns due to the wrong product being sent, the time spent picking products and the delivery speed (although this one can be tricky since it also depends on the quality of the shipping service).

Conclusion

While most companies are already using some form of warehouse organization, slotting is a more efficient way of organizing the stock since it takes all the important factors into account, from the overall layout of items in the warehouse to individual SKUs that need special treatment.

However, if your company commercializes products of similar traits, slotting your warehouse may not make much sense or add much value. Additionally, companies that are going through a sales season, or that simply don’t have the time or resources to implement a slotting strategy, shouldn’t start with the process — stock levels and sales trends change very rapidly and it may end up being a waste of time.

If you find that your warehouse is inefficient but your resources don’t allow you to implement a slotting strategy, working with 3PL solutions could be the ideal solution for you, as they’ll take care of the fulfillment and inventory management on your behalf.

At Outvio, we have an extensive list of 3PL solutions that are available in Europe and can be integrated in a matter of days. Start now!