With so many eCommerce businesses rapidly growing, properly managing inventory often becomes a headache. After all, finding the perfect balance in stock levels isn’t easy: you don’t want too much of anything in order to save costs, but you also don’t want to compromise possible sales with stockout products.

ABC classification allows you to manage your stock efficiently without having a data analyst or warehouse management system (although that can seriously speed up the process). Even though it may be time-consuming in the beginning, the advantages of an ABC inventory classification can pay off soon thereafter.

What is ABC analysis?

ABC (Always Better Control) analysis is one of the most commonly used inventory classification methods. It helps businesses manage and organize their stock in a smart way, optimizes operations, and helps make clear decisions.

In this case, when we say “smart way,” we mean that the items will be located according to the value they bring to the business, instead of other factors like newness, size, category, etc.

Depending on each business, some will do the ABC analysis based on the sales volume or the profitability, but regardless of the criteria they choose, the basics don’t change.

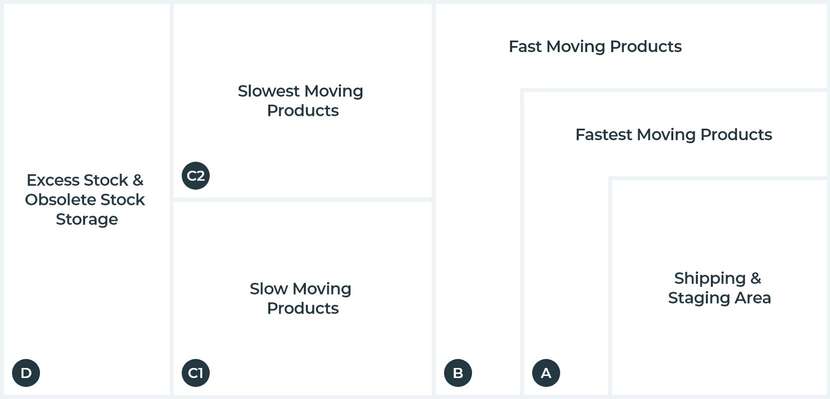

There are at least three groups of items: “A items” are the most valuable to the business, then “B items” and, last, “C items”, which are the least important ones. If your warehouse stores a big amount of SKUs, you may choose to implement more zones in the warehouse for “D items”, “E items”, and so on.

Benefits of ABC inventory classification

ABC inventory classification brings many benefits to an organization, from the way they operate to the results they obtain. These are some of the most important advantages:

An inventory classification fuels efficiency

ABC analysis, when based on product demand, helps businesses allocate resources to items that bring the most sales. In this sense, you will know which items you sell more often, allowing you to maintain a healthy level of stock, give these items the importance and space they need, and build efficient routes for fast picking and packing.

Outvio also helps you be more efficient during your picking and packing process, as it comes with digital on-screen picking lists that can be used across different devices for error-free order processing. Try it now!

Stock forecasting

One of the biggest advantages that businesses with an ABC analysis have over their competitors is a more accurate forecast of future product demand. When online stores can predict how a product is going to perform, it’s easier to maintain healthy stock levels and prioritize those items over low-selling ones.

Improved assessment of a product’s life cycle

Related to forecasting, ABC analysis helps managers assess product life cycles.

Whether they are in the launch phase, growing, or are in the maturity or decline stage, an ABC classification of inventory physically reflects the current situation of any product in your warehouse. It may tell you that it’s time to invest in a product, promote it, slow down the production, or even remove it from your line altogether.

Smaller storage costs and space maximization

Thanks to a better understanding of top-performing items, online stores can plan upcoming restockings based on zones to keep storage costs to a minimum, without compromising on the number of items from the ‘A’ zone.

Instead, they will be able to reduce the space that the C zone takes up, lowering unnecessary costs and providing more space/resources to improve ‘A’ and ‘B’ zone management.

Possibility to set better prices

On the sales spectrum, ABC analysis allows you to choose the best pricing for each item.

When organized based on demand, ABC classification shows the products that have the highest demand. Of course, it’s important to be aware of your current pricing strategy. If you fully rely on low prices to sell, increasing your prices may not have the effect you want and will push your customers to your competitors.

However, once you understand which products are selling well, which are dropping in sales, and which don’t bring enough profits, it will be easy to choose the right price for every product.

How to implement an ABC inventory system

If you follow the Pareto principle (also known as the 80/20 rule), you will need to place approximately 20% of your products in the A zone. These are the items that bring 80% of your profits.

Then, the B zone will have around 30% of goods and bring a 15% of profits, and the C zone will generate about 5% of the revenue and hold the rest of your products.

For an ABC analysis based on demand (not profit):

Step 1: Calculate the annual sales volume per item.

Step 2: List all the products in descending order considering the sales volume.

Step 3: Create the groups of products, placing those that performed the best in the A zone, the next 30% in the B zone, and the rest in the C zone.

This ABC classification method is the best if you want to ensure fast picking and packing and your items don’t need to be handled with machinery or stored in different locations.

For other types of classifications — such as ABC based on dimensions or sizes — you will simply need to sort them by such, creating a range and set space for each zone.

ABC analysis example

We have put together a hypothetical example of how ABC analysis is done, using an online cosmetics store.

This store launches seasonal campaigns when limited-edition products are available (Christmas shower gel, Valentine’s massage oils, or summer scents).

Recently, they have decided to partner up with another brand to sell their tools for a commission. This shed light on the need to implement a more efficient way to classify inventory and they decided to give ABC classification a try.

They place their all-year-round cosmetics in the ‘A’ zone, the current limited edition products together with their partner’s tools in the ‘B’ zone, and the out-of-season products in the ‘C’ zone.

In this case, the online store doesn’t deal with products that require special handling because of their size, weight, or nature. If your business has a larger catalog with items that need to be managed with machinery or put away in a cold room, we recommend doing the classification based on these special conditions, rather than on demand.

Moreover, our example revolved around classifying entire categories of products, but if the data reflects that a series of SKUs from different categories are bringing the most revenue, it can be worth it to put them in the A zone and leave the rest for the B and C zones.

However, the disadvantage of classifying inventory through the ABC method individually, instead of by category, is that the training and re-adjusting time for warehouse workers will be longer and may cause inefficiencies or slower operations, so it should be carefully thought through.

Conclusions

Carrying out an ABC analysis will certainly take time and resources. You will also need to explain to the warehouse operators how it works and what you expect from them, since they can also contribute to pinpointing items that could be moved to another zone to speed up the process.

But, the confusion that will take place during the first couple of days or the investment in time to carry out the classification and placement of items will soon pay off because of better time and resource management in the warehouse.

Faster order processing, more safety, less confusion and stockouts, better demand forecast, and maximization of the space… these are just some of the benefits of using an ABC classification of inventory in a warehouse.

Understand the best criteria to organize items and start taking your warehouse operations to the next level as soon as possible!