Key takeaways

- Pre-shipment starts when the label is created and ends when the carrier receives the package

- Merchants are legally responsible for the package during pre-shipment

- Automate and verify pre-shipment processes to improve speed and accuracy

- 51% of shoppers want real-time visibility during pre-shipment and beyond

- 69% of customers are unlikely to shop again if pre-shipment delays impact delivery times

- Use pre-shipment notifications to drive sales with personalized offers

The term "pre-shipment" isn’t just a routine USPS update—it’s a critical stage in your shipping process that shapes your customers' experience and influences your business success.

Feedback from platforms like Reddit shows that poor communication during this phase can cause customer anxiety, uncertainty, and frustration, ultimately affecting retention rates. That’s why many businesses choose to automate pre-shipment messages using advanced delivery notification software.

Want to know more about pre-transit? We explain what it means, how long it lasts, key legal considerations and optimization practices that all businesses should consider.

What does pre-shipment mean?

Pre-shipment is the first stage of the shipping process where a shipping label is created, but the carrier—like USPS, UPS, or FedEx—hasn’t yet received the package.

At this point, the carrier is aware that a shipment is scheduled, but tracking updates will remain unchanged until the package is physically scanned at the carrier’s facility.

Originally, pre-shipment referred to a USPS shipping notification sent to the customer and the merchant, stating: 'Pre-shipment USPS awaiting item.' Now, it is widely used to describe the entire phase where orders are packed and prepared for shipping, regardless of the carrier.

Pre shipment can also refer to the inspection needed in international shipping for control the quality of the process, ensuring the goods being exported meet the buyer´s specifications,

We can conclude that pre-shipment has three different meanings: the USPS notification, the whole pre-shipping phase, and the international quality control process.

How it works?

The process varies based on your order management system.

If you process orders manually, USPS (or another carrier) typically sends the notification directly after logging shipment details like weight, destination, and shipping method.

On the other hand, if you use shipping software with a notification system, you can leverage trigger technology to customize and send your own notifications, providing a more tailored experience for your customers.

Regardless of the method, the key point is understanding that a pre-shipment status means the order has not yet officially entered the shipping network.

The pre-shipping phase typically includes activities such as:

- Packaging the product securely to prevent damage during transit

- Verifying the accuracy of shipping information and printing the label

- Scheduling carrier pickups or preparing for drop-offs at the carrier’s facility

A lack of a pre-shipment notification after a purchase can negatively impact your customer experience. Customers might assume their original order failed and place another order, leading to unnecessary returns and reverse logistics costs.

How long does pre-shipment take?

The time a package spends in pre-shipment varies depending on the business and its operations. Here’s a quick breakdown:

- Fast, optimized systems: Pre-shipment may take just a few hours

- During busy periods: Holidays or major sales events can stretch this stage to 2–5 days.

Speed up your pre-shipment pass with automations

Tasks like picking, packing, and label printing can quickly become bottlenecks when handled manually, increasing the risk of delays and errors.

To minimize pre-shipment delays, businesses should focus on automation and implementing well-organized pick-and-pack systems.

With a digital and fully automated system, you can reduce pre-shipment duration by:

- Locating items instantly

- Automating label creation

- Processing orders in bulk

- Automating carrier selection

- Printing smart picking lists

Which carriers notify of pre-shipment and how it costs?

Practically all carriers send pre-shipment notifications.

It is the way to confirm to online stores that they have received the pickup request from the warehouse and that the shipment is scheduled.

However, each carrier has its own way of referring to their pre-shipment notifications:

- USPS Uses the term Pre-shipment USPS awaiting item, indicating that the shipping label has been generated but the package has not yet been physically delivered

- FedEx: Displays Shipment Information Sent to FedEx, showing that the shipping details have been provided, but the package is not yet in transit

- UPS Uses notifications like Label Created, confirming that the shipment is scheduled and prepared for pickup or processing.

- DHL Uses Shipment Information Received, which is especially useful for managing international shipments

Pricing

Most carriers, including USPS, FedEx, UPS, and DHL, offer pre-shipment notifications at no additional cost as part of their standard shipping services.

While pre-shipment notifications themselves are free, you may incur fees when generating shipping labels or opting for premium notification features.

What happens if an order is lost, damaged or cancelled during the pre-shipment? Legal considerations

That is a sensitive issue that can sometimes lead to court proceedings.

Until the package is handed over to the carrier, the merchant is generally responsible for its condition and safety.

If issues arise during this stage, the merchant may be liable and required to provide remedies such as refunds, replacements, or exchanges in accordance with consumer protection laws and delivery agreements.

However, responsibility isn’t always clear-cut. In cases of force majeure events, customer errors, or thefts outside the merchant’s control, liability may be mitigated.

Additionally, when third-party logistics (3PL) services are involved, responsibility might fall on the provider, necessitating further investigation to determine accountability.

It is crucial to act quickly to clarify where the responsibility lies.

- Determine if the damage occurred in the warehouse, during packing, or in transit to the carrier

- Check contracts with carriers or outsourced logistics providers to understand liability during pre-shipment

- Take photos and record details of the damaged package to provide evidence

- Consider force majeure situations, customer errors, or theft that may exempt the seller from responsibility

- If outsourced logistics services are used, reach out to determine their level of responsibility

- Consult company policies regarding pre-shipment damages to establish the next steps.

- Notify the customer: Communicate the issue clearly and explain the actions taken to resolve the problem.

A constant oversight of the pre-shipment stage not only resolves immediate issues but also helps identify error patterns and prevent similar situations in the future. Additionally, it is essential to take internal measures to prevent both package damage and losses throughout the entire pre-transit phase.

Who pays the carrier when an order is canceled?

It depends on whether the shipping label has already been purchased. If the label hasn’t been generated or paid for, the seller incurs no shipping costs. However, if the label has been created and paid for, the carrier’s refund policy applies.

Many carriers, such as USPS, UPS, and FedEx, offer refunds for unused labels within a specific time frame. In such cases, the seller can request a refund for the label and avoid paying the carrier.

4 strategies all businesses should know to optimize the pre-shipment stage

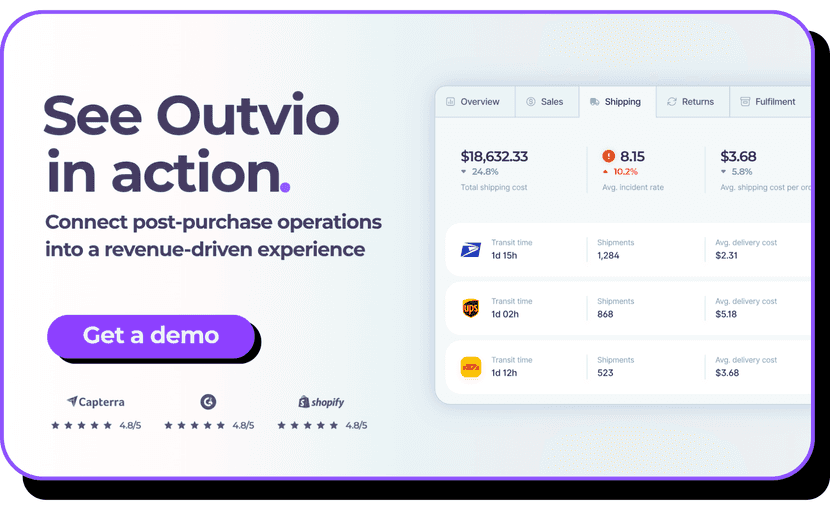

The following best practices are use cases that every business can easily automate with the Outvio platform:

1. Verify orders to eliminate errors and avoid returns

Accurate order verification is critical to reducing returns and maintaining customer satisfaction. Automating this process with Outvio ensures that items are cross-checked against order details before shipping labels are generated.

This minimizes operational errors, reduces reverse logistics costs, and enhances overall process reliability.

2. Send personalized pre-shipment notifications

Personalized recommendations can boost average order value by up to 30%, and customers are 20% more likely to engage when the suggestions are relevant. With Outvio's product recommendation software, you can provide complementary suggestions tailored to each order.

For instance, if a customer purchases running shoes, you can recommend performance socks or offer a discounted water bottle. Adding a time-sensitive offer or free shipping incentive can further encourage immediate action.

Offering the customer a static delivery experience is not enough. If you engage them with valuable communications, you can create a stream of repeat buyers. Outvio provides the functionality to do that. Kerli Reinholm Marketing Manager at Skechers Baltics

3. Consolidate shipments to reduce operational costs

During the pre-shipment or pre-transit phase, order consolidation is a proven strategy for minimizing shipping expenses. Shipment tracking software with real-time data capabilities allows businesses to identify orders headed to similar locations, enabling seamless shipment merging.

This optimization reduces individual shipment costs and enhances carrier efficiency, driving significant operational savings.

4. Use smart carrer selection rules

Dynamic carrier selection is essential for balancing your cost efficiency and delivery performance. With Outvio, businesses can access real-time carrier comparisons to select the most economical and reliable option for each shipment. This flexibility ensures businesses meet customer expectations while keeping logistics costs under control.

In addition, if an issue arises during the pre-shipment phase, the tool will automatically select another carrier to prevent delays in the order