Every seller knows customer satisfaction is the key to getting repeat business. Simply put, a happy customer is likely to return. But what are the chances of that happening if, after a customer trusts your business enough to make an order, they end up facing delays, poor communication, or even missing items?

The truth is customer demands are increasing. They didn’t even slow down in the face of the supply chain crisis brought about by the COVID-19 pandemic. Buyers want free shipping, faster delivery times, and real-time tracking updates. It goes without saying that they expect to receive everything they ordered in one piece. In short, excellent order fulfillment.

That’s why getting the process right with an order fulfillment system is more than just a nice-to-have.

In this article, we’ll explore essential strategiesthat will optimize your order fulfillment process so you can not only meet your customers' expectations, but exceed them.

Order fulfillment and customer expectations

Order fulfillment is the sequence of steps beginning from when a customer places an order to when they receive their package. It includes everything from receiving an order to processing, packing, and shipping it. And, of course, delivery.

Buyers are the most informed they’ve ever been. Also, thanks to giant companies like Amazon, they have grown used to fast and efficient service. So, they transfer those expectations when shopping from smaller stores. They want:

- Fast delivery

- Undamaged items

- Accurate order fulfillment

- Real-time tracking

- Clear and timely communication

- Easy returns

Take the first, for instance. Just look at the statistics. According to Statista, over 60% of customers anticipate their items arriving within 24 hours of ordering them. Many ecommerce stores will report nagging emails and phone logs brimming with calls from customers the day after they ordered an item.

As a business, you must accept that customers don’t know – or care, for that matter – about the commercial pressures surrounding the order delivery process. 91% of them expect a seamless process anyway. You can only meet their expectations as long as there are exactly zero logistics issues, or if they arise, you can handle them in the shortest time possible.

Unfortunately, in reality, issues can (and often) pop up, including:

- Supply chain issues.

- Poor inventory manageent

- Packing errors

- Shipping carrier delays

- Natural disasters

It follows that overcoming these challenges and meeting expectations requires optimizing the order fulfillment process. That is, all the stages and activities involved from when the order was made to when it was delivered – and maybe even beyond that.

The order fulfilment process

So you have a new sale. That’s great, but don’t pop the champagne until you’ve fulfilled the order and your customer has received their items. By the time they do, the order will have gone through a lifecycle usually including these stages:

- Sourcing and receiving

- Inventory storage

- Picking

- Packing

- Shipping

- Delivery

The order is fulfilled when the customer has received the item. But what if they decide to return it? Order fulfillment handles that as well.

Some businesses use an in-house model where employees handle the various stages of the order fulfillment process. However, there’s usually at least a little outsourcing with third-party fulfillment services involved.

Best practices for optimizing order fulfilment processes

Mishandling any of the stages highlighted in the previous section can have a cascading effect, leading right up to a pretty displeased customer. Keep in mind that it doesn’t take more than two poor CX instances for 86% of customers to find the door and never come back.

You don’t want that to happen. The tactics below will come in handy for optimizing your order fulfullment processes:

1. Streamline receiving processes

How you process incoming shipments sets the tone for the order fulfillment process. If you don’t receive and process items quickly before moving them to inventory, you’re looking at long wait times and, ultimately, dissatisfied customers.

That’s why having a well-organized warehouse with a standardized operating procedure is a non-negotiable. A step-by-step procedure means items can come in, be unloaded, verified, clearly labeled, and stored efficiently.

What’s more, damaged items should be returned to the manufacturer as soon as possible for replacement. That’s something no business wants to deal with, but you can’t afford to keep it hanging.

2. Automate wherever possible

Human error is inevitable in a fully manual order fulfillment process, whether it’s during picking, packing, communication, or inventory management. A pick-and-pack software approach eliminates these errors and, in doing so, speeds up the process.

What’s more – and this is just as important – you’re saving significant labor costs and creating happier employees by improving their conditions.

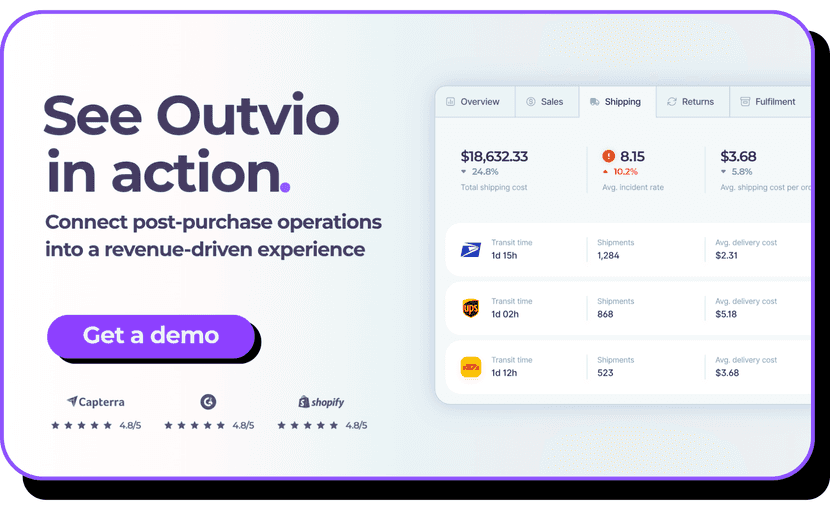

You can apply technology and automation everywhere. For instance, an order management solution like Outvio can automate shipping and fulfillment, complete with incidence and returns management. A warehouse management system can handle inventory management and order processing so employees don’t waste time on manual data entry or misread packing slips.

Automated storage and retrieval systems (ASRS) and robots automatically store and retrieve goods from storage, reducing the number of touching and handling. An auto-attendant business telephone system can handle call management and routing automatically.

Make sure to choose online shopping systems with apps and integrations that allow you to automate stuff wherever you can.

3. Diversify parcel fulfillment partners

Previously, businesses stuck to a single carrier to handle their shipments, but the COVID-19 pandemic clearly showed just how risky that was over the last few years.

Relying on one provider means labor strikes, capacity limits, weather delays, and other unforeseen circumstances can wreak havoc on your order fulfillment.

Imagine having a ton of deliveries to make during Black Friday, only to find out your carrier is experiencing capacity issues.

But don’t just jump on the first carrier you come across. Conduct thorough evaluations before adding a new, reliable partner. What’s more, invest time and effort into negotiating the best deals and schedules that align with yours. Plus, they should have good coverage in terms of their warehouse locations.

4. Invest in packaging

Packaging is more than just aesthetics. It can, in fact, play a key role in pleasing customers and bringing them back.

For one, proper packaging prevents your goods from damaging. That’s really essential if you’re trying to minimize returns, considering a survey showed that 81% of customers have sent back products they bought online because they were damaged or defective. So, you want to invest in high-quality packaging materials that ensure your items arrive in perfect condition.

Of course, that doesn’t mean you should discount visual appeal, especially in these days of unboxing videos.

Eco-friendly packaging is another needle mover. 80% of customers are willing to buy products that come in sustainable packaging, and up to 82% will even pay more.

5. Set clear delivery expectations and allow tracking

Transparency is the cornerstone of delivery expectations. As we’ve mentioned earlier, customers want faster deliveries and are actually willing to pay more for them. But that’s definitely not something you want to take advantage of if you don’t have the capacity to deliver.

Maybe you can’t compete with Amazon’s 1-day delivery times, but try to offer accurate delivery time windows based on location and shipping method at checkout. Of course, this means you must have reliable carriers.

Also, provide real-time order tracking so customers can have instant updates whenever they want. That kind of visibility builds trust and reduces pressure.

Sure, they have towering expectations, but customers are surprisingly forgiving and flexible if you communicate well. If you tell a customer to expect their item in three days, and delays increase that time to 4 days, the extra 24 hours without explanation is enough to get them really frustrated – so make sure to keep them in the loop.

6. Prepare to handle returns

Some new businesses ignore this, hoping they will never have to deal with it. Unfortunately, even if you’ve checked all the right boxes, it's almost inevitable. A customer could simply change their mind about an impulse buy and decide to return. And yes, returns fall under order fulfillment.

How prepared are you to handle returns? Develop a clear (and easy-to-understand) policy with a standardized procedure. It should outline the conditions under which you’ll accept returns, timeframes, and associated costs.

Automation can come in handy here. Returns management software will save you time and money while reducing customer frustration. Some services, like Loop Returns, integrate returns and order tracking under one solution.

7. Track metrics and performance

So you think you’ve crafted the perfect order fulfillment system. But how can you know for sure?

How do you know how well you’re doing, for that matter? Also, when (and where) do you make adjustments? The answers to these questions lie in keeping an eye on the right metrics and KPIs so you can tweak or overhaul your system when necessary.

The performance indicators you should track depend, in large part, on how complex and mature your processes are. Here are some of the important ones:

- Total order cycle time

- Average shipping time

- Percentage of deliveries on time

- Fulfillment accuracy rate

- On-time ready to ship

- Inventory accuracy

- Return rate

Great figures in your KPIs can be great for marketing. For example, announcing that “99% of our orders are shipped within 24 hours” can boost confidence and increase conversion rates.

Final thoughts

Becoming intentional about optimizing your order fulfillment processes can only be a positive for your business. It will keep you within reach of increasing customer expectations and help you satisfy them. Better experiences translate to more sales, revenue, a better reputation, and loyal customers. It’s also great for reducing your costs and keeping your employees productive.

In this article, we highlighted and discussed several practices you can start implementing immediately. Remember to track your progress and iterate where necessary.

Related reading: