Expanding retailing operations while keeping control over inventory isn’t an easy task. Having stockouts of the most successful items and too many of the least popular purchases can seriously harm your business. There are a number of ways to solve this problem, but kitting is being seen by many as the solution to minor stock problems.

For other businesses, kitting is the core of their operations, meaning that they only sell kits or product bundles. This is the case of subscription box services, for example.

There are many advantages to this approach, which is why we want you to know all about it so you can evaluate if it’s worth it for your business to implement this strategy.

What is kitting in a warehouse?

Kitting is the process of building product bundles in a warehouse in order for them to be sold together. In this way, retailers can create kits (hence the word ‘kitting’), grouping several SKUs under a new product (one unique SKU).

Kitting can be done in different ways, from classic product bundles to subscription boxes that are shipped every month. Both practices are part of a kitting strategy.

Kitting vs. product bundles

Product bundles are a compilation of two or more items into a single product, meaning several SKUs are combined in a single SKU. Kitting is the process of putting together product bundles.

Product bundles are ultimately the result of a kitting practice.

Benefits of kitting

Kitting has become a regular practice for many retailers. In fact, there are businesses that fully run their operations with kitting in mind. Therefore, it’s easy to assume that there are many benefits of kitting. Here are some of the most important ones:

Lower fulfillment costs

By putting together one unique SKU, the number of products available at the warehouse will be significantly reduced. But this is just the tip of the iceberg.

Combining the most popular items or creating a bundle of products that are frequently purchased together means that the fulfillment time — and cost — will be reduced. The difference between picking one single box and collecting three or four different SKUs ends up making a difference in terms of time. The results are less time, fewer costs, and faster deliveries.

Warehouse operators will only need to place a single box in the shipping package; only one item to verify means less room for errors. The result? Less errors, lower costs, and more customer satisfaction.

Faster picking and packing

As we mentioned above, with less SKUs to go through, the picking and packing process is much faster. This has an added advantage for the customer: with shorter order processing times, they should be receiving their products faster, increasing the quality of the purchasing experience and making them more likely to buy from you again.

When the bundles are prepared ahead of time — although, you will need some preparation and time to create the bundles — orders can be fulfilled faster and the picking and packing process will be as short as possible.

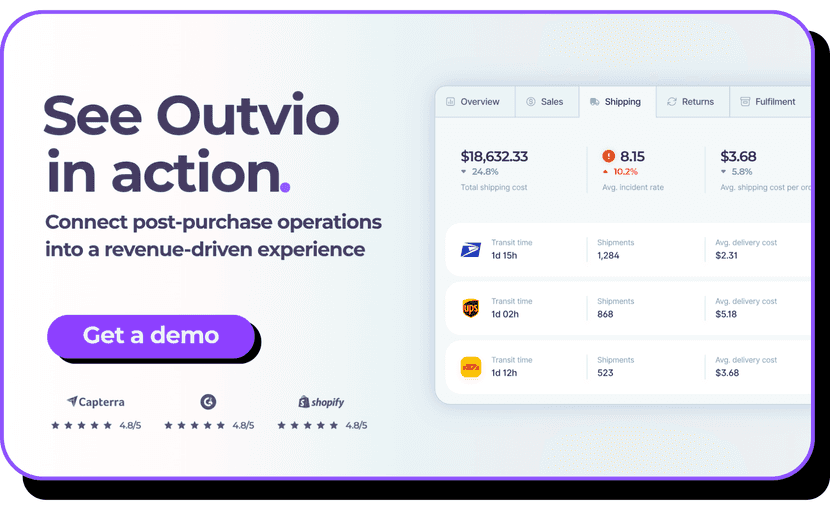

If you want to make your warehouse operations more efficient, Outvio has all the functionality you need. On-screen picking lists, an item-verification system to ensure 100% error-free orders, and bulk-printing possibilities to speed up the shipping label printing process. Try it now!

Larger catalog of products and higher average order value

Coming up with new products isn’t an easy task. You first need to have an idea, study the possibilities in the market, develop it, test it, find the best way to market it, etc. By selling products both individually and also as part of a set, you will be expanding your catalog of products in an effortless way.

Source: Manjunath Kiran

Perhaps one product doesn’t particularly sell well on its own; this is the chance to recover some of your initial investment. By bundling items that aren’t selling well with other products that have been successful among your customers, you can reduce the anxiety that comes with purchasing a kit of unknown products.

You can even create a product bundle with your top seller, a product that not many customers know about, and a new product that you are thinking of adding to the permanent catalog. The possibilities are endless.

When customers encounter kits, they value the fact that they are saving money on their purchase. In reality, kits encourage larger purchases since buyers may be adding products to their cart without actually needing them. Kitting doesn’t only have the benefit of increasing sales by expanding your product catalog at a low cost, it also increases the average order value while reducing shipping and fulfillment costs.

Cheaper shipping rates

If you come up with efficient packaging that protects the products but takes up only the necessary space, you will be saving on shipping costs.

Instead of protecting three or more products, you will be able to protect just one box, where items are placed in a safe manner. In this way, from shipping a standard box, you will be able to ship a box that may be half the size, considerably reducing the shipping costs.

Moreover, if you choose to reduce the amount of packaging you use, you will be able to make shipments with a smaller volumetric weight. This may be one of the most efficient ways to have cheaper shipping rates.

Regardless of if the customer pays for the shipment or you do, it will make the shipping process cheaper and more efficient.

Less resources needed for packaging

Kitting can also be a great solution if you are looking into ways to reduce the cost of packaging. Instead of packing each product individually to later put it in a larger shipping box, you can simply get rid of the secondary packaging.

For instance, for products that need a container, retailers typically use a box with additional specifications on the packaging. Think of cosmetics, food, electronics, stationery, etc.

Source: Mac Cosmetics

Instead of using boxes that add little value to the customer (but do have an impact on your business’ bottom line), you can reduce the packaging cost by placing different products in a single, beautifully designed box.

Because of the popularity of kitting, finding packaging companies that can provide these kinds of boxes isn’t difficult or very expensive. However, if you want to really leave an impression on the buyer, you can personalize your packaging to include your branding, providing a more consistent purchasing experience.

More space in the warehouse

By preparing kits in your warehouse, you will be reducing the number of SKUs and will be able to cut down on secondary packaging, too.

Less SKUs with smaller dimensions means that your warehouse will be easier to go through and you will leverage some space in the packing area since kits are ready-to-go items.

By maximizing the space you already have, you can cut down on warehouse costs simply by not needing to expand it, and you will be able to store more items. Ultimately, you will have more room for new products and more stock of already existing products that may have a high-restocking frequency.

More control over inventory levels

Fewer SKUs and a more organized warehouse layout mean that it will not only be easy to go through inventory and the picking process, but it will also be easier to see, at a glance, which items you are running low on and which products aren’t selling well.

With regular multi-product orders, you can’t see how many available items you have of every SKU. However, when you do a full-kitting strategy, it’s fast and easy to see if you need to re-order some products or if you have too many of another.

Kitting process

Now that you know the major benefits of kitting, you may be asking yourself how to carry out the kitting process and how it may affect other areas of your business.

Kitting and manufacturing

Part of the kitting process may actually be traced back to the manufacturing process. Although this isn’t typical, businesses like Hello Fresh need to think of kitting as part of their product development strategy, the product being a collection of recipes that are delivered every month with the ingredients to cook them.

Source: HelloFresh

In their case, when building a recipe, they need to have specific ingredients on hand and individually prepare them so they can safely reach their final destination.

Another example of a similar company is Daily Harvest. Their operations are a bit different, as they deliver frozen food that only needs heating up or blending.

Source: Daily Harvest

Kitting and assembly

Having covered some of the most complex ways in which kitting takes place, it’s time to look at easier ways of implementing this in a warehouse: by assembling different products in a bundle.

For a kitting strategy to make sense and provide all the benefits that we mentioned above, it’s fundamental to prepare these kits ahead of time.

For that, we recommend making the most out of slow periods by preparing these kits before orders start coming in. This way, by the time customers begin to place their orders, you will already have those kits ready to be packed and shipped.

Kitting and warehouse

Kitting typically takes place in a warehouse and, like the picking and packing process, it should be deeply thought through in order to make it as efficient as possible.

In this sense, we suggest looking at the most common product combinations on your website, and offering them as a product bundle. You don’t need to stop there, though. You can also create product combinations and include a top-selling item, a basic item that can be used by most buyers, and an additional item that you may want to promote.

Kitting is proven to be very effective for reducing costs and maximizing warehouse floor and packing areas. It’s no wonder why we often find that kitting and warehouse goes together!

Kitting and fulfillment

The last stage before the order is shipped is the fulfillment process. When you reach this point, you’ll start to notice the advantages of kits for warehouse operations: faster picking and packing, a fulfillment process with less errors and more simple operations, and more safety for workers thanks to maximizing the space.

Kitting can be often seen as a way to fulfill orders, as some retailers only do it at a later stage. The same operators that will be putting together orders are likely putting together the product bundles, too.

In any case, kitting can be implemented as an additional source of revenue, as well as a core operation for the business, but it will always be tightly linked to the production and fulfillment stage.

Conclusions

Kitting, although not for every business, can be easily implemented as a way to sell slow-moving products, promote product launches, increase the average order value, or to reduce fulfillment time and costs for common product combinations.

Regardless of why you choose to do it, you will experience amazing benefits when implemented properly. Your manufacturing, warehouse, and fulfillment operations will see the impact of kitting, and your customers will receive their orders faster and likely with less errors, thanks to pre-made kits.

If having efficient eCommerce operations is something that concerns you, discover all the advantages of using Outvio as the backbone of your post-checkout activities. Sign up and start using it for free.